Although there are a several types of poultry raised and consumed in Thailand, chicken is the most important. There are three main types of chicken in Thailand: broilers, layers and native chickens. Broiler cage and layer chicken cage are different and specially design.

From an economic perspective, broiler meat is the most important poultry product, both for domestic consumption and export. As in most countries, egg production from layers is mainly for domestic consumption.2 Native chickens have been raised for several purposes; they include backyard chickens raised mainly for household consumption and small-scale trade; farm raised birds for sale in specialty markets; and, to a lesser extent, chickens raised for recreation or ”sporting” purposes, including fighting cocks. Broiler and layer farming, account for most of the poultry production in Thailand. About half of the country’s chickens are raised in central Thailand – a relatively small but highly populated region; second in terms of poultry production is the north-eastern region, which is physically the largest region of Thailand. Most of the exported chicken comes from farms in the central region.

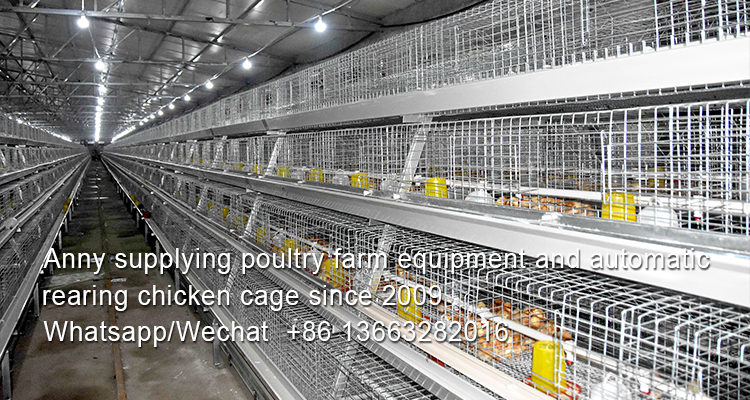

The common type chicken cage are suitable for small scale poultry farmers such as 1000 birds to 50000 birds, large poultry farm such as rearing 80000 birds or more to use full automatic layer chicken cage with automatic feeding, drinking, egg collection and manure belt system

Today, the poultry sector occupies more than half of Thailand’s total meat and feed production, ranking number four in Asia’s poultry meat production with a total of almost 1.8 million tons in 2015, which is expected to increase 5% in 2016. our first order of Automatic chicken cage and poultry equipment are in 2016

Due to a potential growth in export demand and an anticipated increase in chick production capacity, Thai chicken meat production is forecast to further increase from the 2016 level by 5-7% in 2017. Brazil and the US are Thailand’s main competitors, mainly due to the lower production costs. Export trends approximately 70% of the total poultry production in Thailand, 1.2 million tons in 2015, is consumed domestically, whereas 30% is exported. Due to Thailand’s growing tourism industry and gradual economic recovery, domestic consumption of chicken meat is expected to increase by 4-5% in 2017, from around 670 million tons in 2016. Thailand accounts for almost 15% share of 76 million hen and duck eggs production (2013). Thailand’s largest poultry export markets are the EU and Japan. Other export markets include Singapore, Malaysia, and South Korea and Hong Kong, but these are far less big in size. Due to the lower price, traditional culture and - in particular for Malaysia and Indonesia - religious reasons, the main protein source in Southeast Asia is poultry. Only Vietnam and Philippines consume pork as the main source of protein.

Most Thai farmers, generally, keep their chicken in the backyard. But some farmers may take their birds to the fields when endemic diseases break out in the villages and/or during crop growing and harvesting seasons. Chickens are penned to protect them from predators and/ or thieves at night. A pen is usually located under a rice storage for ease of construction; if it stands alone it will still be close to the house. Chickens are fed twice daily, in the morning and evening, mostly by women. Chickens can move freely with their flock scavenging around for edible insects, seeds and fresh plant parts. In most cases, there are no vaccination and de-worming for chicken; but some farmers may have local herbs for prevention and/or curing. This practice tends to satisfy the farmers involved. A family generally keeps one rooster with three to five hens to form a flock, annually. This helps to maintain pecking order and reduce fighting in the flock. In a year, such flocks can produce up to 90–150 day-old chicks, equivalent to 30–75 marketable birds of 1.0-1.5 kg body weight at four to five months of age. The number of chickens per household varies greatly depending on time of the year and capacity of the farmers. From October to February (cool and dry), the number of day old chicks running around is at its greatest, and the chicks’ growth rate is also high. This is because of the higher hatching rate, and the availability of plenty of natural feeds and of crop by-products.

Our China battery layer chicken cages and poultry equipment Factory

Hebei Best Machinery And Equipment Co., Ltd.,found in 1996, 360KM from BEIJING city, from raw materials to finished products, strict implementation of ISO 9001:2008 quality management system.

Our Nigerian branch battery chicken cages and poultry equipment Factory

Rose of Sharon Plaza by Oko filing bus stop, Igando road, opposite Oando filling station, Lagos, production line is from our Chinese factory directly, 3 to 5 years longer using than local battery cages.

If you have any plan on poultry farm, please free to contact me, I supplying farm equipment and automatic rearing battery cage since 2009.

Anny Wang, Whatsapp/Wechat +86 13663282016