E-mail:sales@bestchickencage.com

E-mail:sales@bestchickencage.com

Summary

Selecting the right poultry housing system directly affects production efficiency, hygiene, and profitability. this article compares the automatic layer battery cage and deep litter system, helping farmers choose the best solution for modern egg farming needs and efficient poultry equipment management on their poultry farm.

Battery cage system

Poultry deep litter system

Key Comparison Indicators

| Indicator | Automatic Layer battery cage System | Deep Litter System |

|---|---|---|

| Space Utilization | High (multi-tier structure) | Low (flat system) |

| Labor Demand | Low (automated) | High (manual) |

| Animal Welfare | Moderate | High |

| Initial Investment | High | Low |

| Hygiene Control | Easy | Difficult |

| Egg Cleanliness | High | Moderate |

| Suitable for Large Scale | Excellent | Medium and small scale only |

Application Scenarios And Advantages

| System Type | Suitable Scenarios | Advantages |

|---|---|---|

| Automatic Layer battery cage System | Large-scale, commercial, high-yield poultry farms | High space efficiency, easy management, clean eggs, high automation |

| Deep Litter System | Organic, welfare, or small-scale poultry farms | Eco-friendly, more activity for birds, recyclable bedding |

Automatic Layer Battery Cage System

Definition And Structure Description

The automatic layer battery cage system uses a metal support frame (vertical posts and horizontal beams) arranged in multi-tier layers (3–12 tiers). It integrates automatic feeding, drinking, manure removal, and egg collection systems, enabling high-density and mechanized layer farming. battery cage design ensures eggs roll out smoothly. It is an essential part of modern poultry equipment for any commercial poultry farm.

Advantages

1. High space efficiency: Multi-tier battery cage design increases stocking density per square meter.

Deep Litter System

Definition And Structure Description

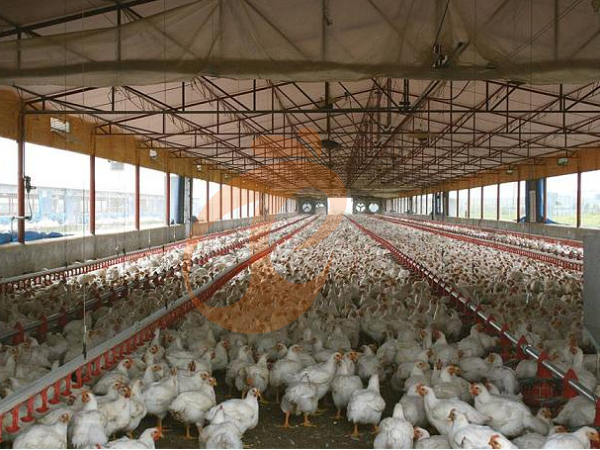

The deep litter system houses layers on a floor covered with thick bedding materials such as sawdust, rice husks, or straw. Birds can move freely. The litter absorbs manure and decomposes naturally through microbial activity and manual turning. battery cage is less used here, but proper poultry equipment can still improve efficiency.

Advantages

1. Higher animal welfare: Birds have more space to move.

Frequently Asked Questions (FAQ)

1. Which system saves more labor?

The automatic cage system, due to high automation and less human work.

2. Which system has higher production?

The cage system, because of higher stocking density and better feed efficiency.

3. Which system is cleaner?

The cage system, as eggs are separated from manure and remain cleaner.

4. Which system is more eco-friendly?

The deep litter system, since bedding can be composted into organic fertilizer.

5. Which is better for Nigeria?

For large-scale commercial poultry farms, the automatic battery cage system is ideal. For organic or welfare farms, the deep litter system is more suitable. battery cage improves management and is part of essential poultry equipment.

Recommendation From VANKE China–Nigeria Branch

In Nigeria, land is relatively abundant, but labor costs are rising. VANKE recommends combining the advantages of both systems:

Use automatic layer battery cages for large-scale, high-output poultry farms integrating automatic feeding, manure removal, and egg collection.

For eco-friendly or specialty brands, adopt deep litter systems for better welfare and differentiation. Focus on ventilation, temperature control, manure treatment, and feed system integration to improve poultry farm productivity and bird health.

Battery cage systems help optimize production and integrate smoothly with other poultry equipment.

Contact Vanke Poultry Equipment (China-Nigeria Office)

How many plots of your land, cleaned or weeds still?

Which month starting building chicken pen?

How many birds starting like 2.000~5.000, 10.000~30.000, 100.000+?

Where is your farm?

VANKE MACHINERY AND EQUIPMENT CO., LTD

What'sapp : +234 8111199996, +8618830120193 (24 hours online)

Email : sales@bestchickencage.com

Location: After Sinoma Office, 200 Meters Near Danco Filling Station, Lagos/Ibadan Expressway, Lagos State, Nigeria

SEND YOUR MESSAGE TO US

(* We will reply your inquiry to this Email as soon as we see it.)RECENT BOLGS

Comments

CONTACT US