E-mail:sales@bestchickencage.com

E-mail:sales@bestchickencage.com

YOU LOCATION:Home > Products > Battery Cage

H Type Automatic Layer Battery Cage For Sale:

Design, Types, Size, Structure, Advantages, And Price

H type automatic layer battery cage is designed for medium and large commercial layer farms aiming such as 40,000+ chickens for higher egg production efficiency, better flock health, and manure standardized management.

By implementing an H-type system, farms can increase egg production by 4–7 times per square meter, reduce labor costs by 60–75%, improve feed efficiency by up to 10%, and reduce mortality and egg breakage.

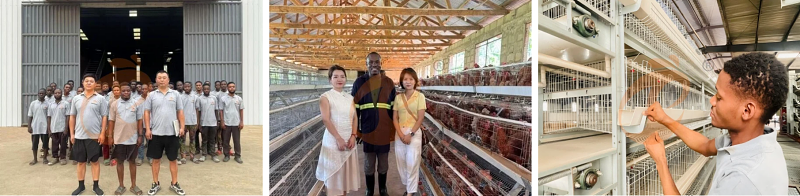

Nigeria-China Local Leading Battery Cage System Manufacturer and Supplier

Why Choosing Vanke And Vanke H Type Automatic Layer Battery Cage For Sale?

A short video to understand VANKE's one-stop service

1. Turnkey solution: We have over a thousand farming projects and experiences in Nigeria.

2. Understand you better: Having a better understanding of the project plans and farm equipment selection that are suitable for Nigeria.

3. Purchase with peace of mind: In our warehouse, you can find thousands of components, which is very beneficial for product upgrades.

Lagos office: After Sinoma Office, 200 Meters Near Danco Filling Station, Lagos/Ibadan Expressway, Lagos State, Nigeria.

Hot Sale Types Of H Type Automatic Layer Battery Cages

The popular A type battery cage design

Here is a shorter video introducting its whole structure such as cage frame, automatic sytem of watering, feeding , egg collection and theirs working principle.

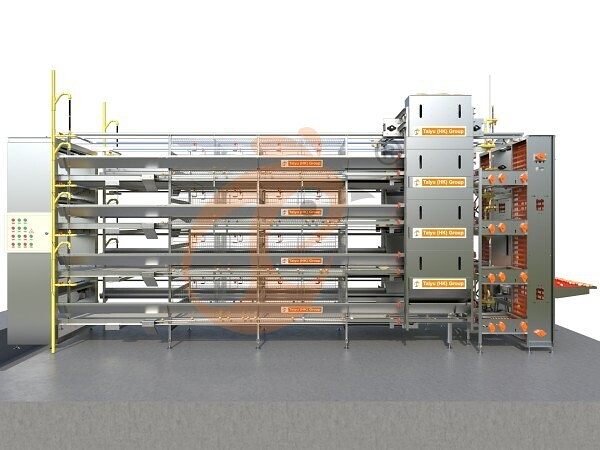

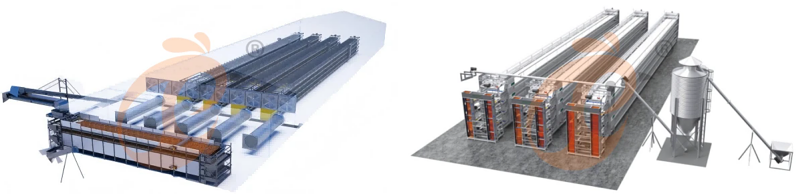

H Type 4 Tiers Fully Automatic Layer Battery Cages In Poultry House

1. Hot sale type 1

- Tiers: 4 tiers

- Capacity/set: 128 chickens

- L X W X H: 1.25m by 1.25m by 3.0m

- House Size: 50 x 10 x 5.8-17 (L x W x H): 12,672 birds

- House Size: 100 x 10 x 5.8-17 (L x W x H) 15,480 birds28,800 birds

2. Hot sale type 2

- Tiers: 8 tiers

- Capacity/set: 160 chickens

- L X W X H: 1.25m by 1.25m by 7.0

- House Size: 50 x 12 x 4.15-5.25 (L x W x H): 25,344 birds

- House Size: 100 x 12 x 4.15-5.25 (L x W x H): 57,600 birds

3. Hot sale type 3

- Tiers: 12 tiers

- Capacity/set: 384 chickens

- L X W X H: 1.25m by 1.25m by 10.3

- House Size: 50 x 12 x 4.15-5.25 (L x W x H): 38,016 birds

- House Size: 100 x 12 x 4.15-5.25 (L x W x H): 86,400 birds

To obtain the quotation, please Whatsapp 24 hours online/Mobile: +2348111199996, +8618830120193

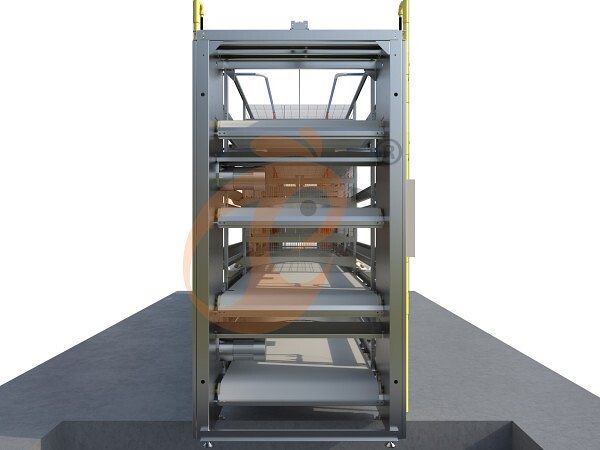

Structure Of H Type Automatic Layer Battery Cages

Our H type fully automatic battery cage poultry farm case, watch its practice application more clearly

Case 1 - 80,000 chickens a house

Case 2 - 540,000 chickens poultry farm turnkey project

To obtain your farm-specific plan, please Whatsapp 24 hours online/Mobile: +234 8111199996, +86 18830120193

| No. | System / Item | Specification |

|---|---|---|

| 1 | Cage Body Structure |

- Material: Hot-dip galvanized steel - Zinc Coating Thickness: 200–450 g/m² - Corrosion Resistance: 20–25 years - Egg-Rolling Angle: 7–9° - Load-Bearing Frame: Flat-iron galvanized steel - Frame Load Capacity: 800–1200 kg per column |

| 2 | Automatic Watering System |

- Drinker Type: Nipple drinking system - Nipple Flow Rate: 20–30 ml/min - Water Pressure: 0.2–0.5 bar - Height Adjustment Range: 0–35 cm - Drip Cup Efficiency: >90% water waste reduction - Ammonia Reduction: 20–35% - Water Supply Capacity: 3,000–4,500 birds per line - Nipple Material: SUS304 stainless steel |

| 3 | Automatic Feeding System – Spiral/Screw |

- Feeding Type: Spiral / Screw system - Feed Delivery Speed: 35–45 m/min - Transport Capacity: 600–900 kg/hour - Max House Length: 120–150 m - Feed Distribution Error: <5% - Motor Power: 0.75–1.5 kW |

| 4 | Automatic Feeding System – Chain |

- Feeding Type: Chain feeding system - Chain Speed: 20–30 m/min - Feed Uniformity Error: <3% - Feed Wastage Reduction: 5–12% - Motor Service Life: ≥20,000 hours |

| 5 | Manure Removal System |

- Belt Material: PP reinforced belt - Belt Thickness: 1.0–1.2 mm - Cleaning Accuracy: >98% - Manure Capacity: 8–12 tons / 10,000 birds / day - Moisture Reduction: 40–60% - Belt Speed: 2.5–10 m/min - Motor Power: 0.55–0.75 kW per belt |

| 6 | Automatic Egg Collection System |

- Egg Belt Width: 350–550 mm - Vertical Lift Capacity: 15,000–30,000 eggs/hour - Horizontal Speed: 6–20 m/min - Egg Breakage Rate: <0.8% - Central Sorting Capacity: 10,000–200,000 eggs/hour |

| 7 | Environmental Control – Ventilation |

- 50-Inch Fan Air Volume: 42,000–45,000 m³/h - 36-Inch Fan Air Volume: 20,000–23,000 m³/h - Fresh Air Requirement: 5–6 m³/kg live weight/hour - Negative Pressure: -25 to -40 Pa |

| 8 | Environmental Control – Cooling Pad |

- Pad Thickness: 100–150 mm - Cooling Efficiency: 70–90% - Temperature Reduction: 8–12°C - Water Circulation: 2–4 L/min per meter |

| 9 | Lighting System |

- LED Power Consumption: 3–6 W/m - Light Intensity (Rearing): 8–12 lux - Light Intensity (Laying): 14–18 lux - Programmable Cycles: 16–24 periods/day |

| 10 | Environmental Controller |

- Temperature Accuracy: ±0.1°C - Humidity Accuracy: ±3% RH - Controlled Devices: Fans, pads, heaters, inlets, alarms - Energy Saving: 18–30% annually |

The intelligent control system is an essential component of modern large-scale layer farms, especially when used with multi-tier H-type layer cages. It integrates all equipment—including feeding, drinking, manure cleaning, egg collection, ventilation, and lighting—into a centralized digital platform.

Price Range

Pricing varies depending on tier count, automation level, materials, and included systems:

Cage body per group: USD 150–350

Fully automated system per 10,000 birds: USD 9,000–15,000

Additional costs may include shipping, installation, environmental control, and accessories

For accurate quotes, manufacturers require house layout, desired tier count, bird density, and system preferences.

|

Type |

Tier/Set |

Size(L x W x H)/Unit(M) |

Cell Size(L x W x H)(CM) |

Cells/Unit Per Set |

|

H1 |

4 |

1.25 x 1.25 x 3.3 |

60 x 62.5 x 48 |

16 |

|

H2 |

8 |

1.25 x 1.25 x 7 |

60 x 62.5 x 48 |

32 |

|

H3 |

12 |

1.25 x 1.25 x 10.3 |

60 x 62.5 x 48 |

48 |

|

H4 |

16 |

1.25 x 1.25 x 14 |

60 x 62.5 x 48 |

64 |

House size and birds capacity

|

Component |

Regular Data |

|||

|

Cage Model |

4 tiers |

8 tiers |

12 tiers |

16 tiers |

|

House Size: 50 x 10 x 5.8-17 (L x W x H) |

12,672 birds |

25,344 birds |

38,016 birds |

50,688 birds |

|

House Size: 100 x 10 x 5.8-17 (L x W x H) |

28,800 birds |

57,600 birds |

86,400 birds |

115,200 birds |

|

Standard Cage Dimension (L x W x H) |

1.2 x 1.2 x 3.3m |

1.2 x 1.2 x 7m |

1.2 x 1.2 x 10.3m |

1.2 x 1.2 x 14m |

|

Birds Per Set |

128 birds |

256 birds |

384 birds |

512 birds |

For reference only, the exact size is based on the actual needs of the poultry farm and customer requirements, or our exact quotation.

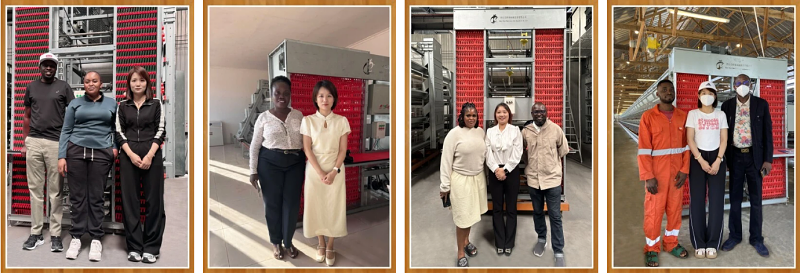

1. Since its establishment in 2011, we have rich experience in localization services.

Nigerian local team

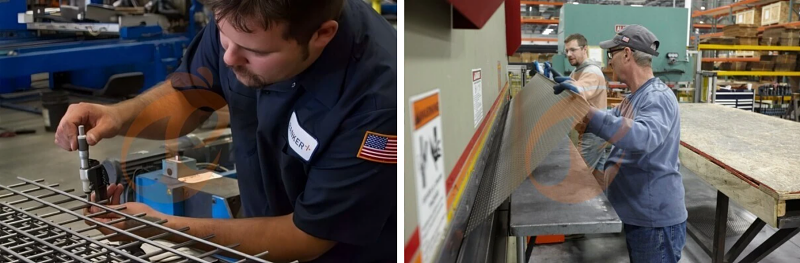

2. Constant communication with the United States and Europe, make high-quality battery cage and equipment.

Engineer inspection

3. Lagos local production, save customers 10% to 30% of costs.

Nigerian Factory, workshop and materials

4. Constantly innovate technologies, tailor intelligent project solutions for you.

Intelligent solution

5. Constantly expanding the team, the headquarters in Hong Kong and branches in Nigeria, Tanzania and Ethiopia are joint management.

Branches of China, Nigeria, Tanzania and Ethiopia

Vanke Machinery & Equipment Nig Ltd have serviced farmers and distributors since 2010.

Gain the high trust and recognition from customers to now.

Following farmers are some of our clients, welcome you!

Contact: Whatsapp 24 hours online +234 8111199996.

ADD: after Sinoma Office, 200 meters near Danco Filling Station, Lagos/Ibadan Expressway, Lagos State, Nigeria.

7 Detailed Advantages Of H Type Layer Battery Cage System

1. Maximum Stocking Density

H-type vertical layout allows 4–7 times more birds per square meter compared with traditional floor systems, maximizing output per house.

2. High Automation, Reduced Labor Costs

Automation can reduce labor needs by 60–75%, enabling precise control of feeding, watering, manure removal, and egg collection.

3. Cleaner Eggs, Lower Breakage

Egg-rolling trays and gentle conveyors reduce egg breakage to 0.5–1.5%, improving profitability and egg quality.

4. Improved Ventilation and Health

Tiered cage design ensures 5–6 m³ of airflow per kg of live bird per hour, reducing heat stress and respiratory disease.

5. Durability and Longevity

Hot-dip galvanized steel ensures 20–25 years of service life, lowering replacement costs and maintenance.

6. Better Feed Efficiency and Productivity

Feed consumption: 110–120 g/day per layer

Yearly egg production per bird: 280–320 eggs/year

Feed conversion ratio improved by 5–10% due to controlled feeding

Mortality rates reduced by 2–4%

Manure moisture reduced by 40–60%, decreasing disease risk

7. Economic Benefits

Payback period: 10–18 months depending on scale

Annual labor savings with fully automated systems: USD 8,000–30,000

Increased egg yield and reduced breakage improve profit margins

Supports expansion and long-term cost savings

1. All fittings are packed by wooden pallets and boxes, plastic wraps and boxes, nude packing, it depends.

2. Local factory and warehouse from branches of Ethiopia, Tanzania and Nigeria, depends on your order.

3. Full or less container from China branch by sea, depends on your order.

Nigerian factory, warehouse and delivery

Container shipping from China to Nigeria

Engineer installation In Nigeria

SEND YOUR MESSAGE TO US

(* We will reply your inquiry to this Email as soon as we see it.)RECENT BOLGS

Comments

CONTACT US