E-mail:sales@bestchickencage.com

E-mail:sales@bestchickencage.com

YOU LOCATION:Home > Products > Chicken Cage

Chick battery cage is for 100 - 10,000+ chicks a house, at 2 - 12 weeks day old chicks for future laying. It is lifespan is 25+ years.

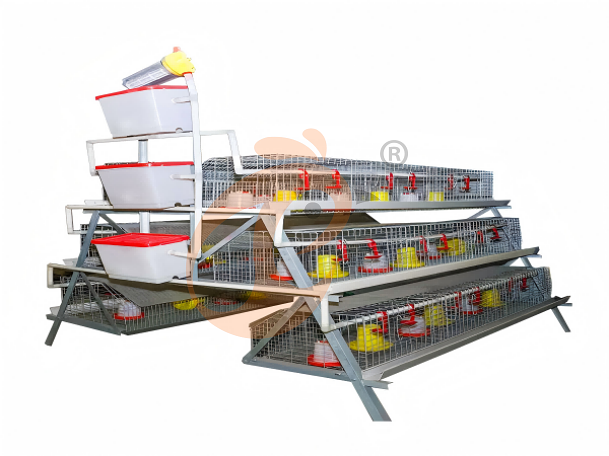

Chick battery cage is with "A" frame, also named A type semi-automatic chick battery cage.

The lifespan of battery cage made by VANKE are 5 years higher than market.

Learn introduction of "chick battery cage is for 10,000 - 50,000+ chicks a house" and "chick battery cage for 50,000 - 100,000+ chicks a house", please check PRODUCTS

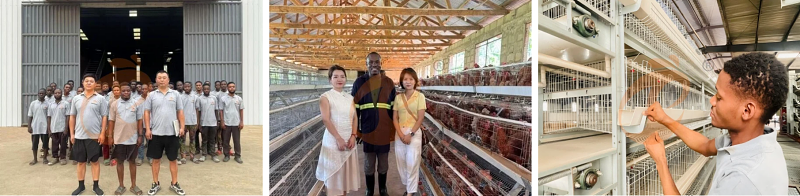

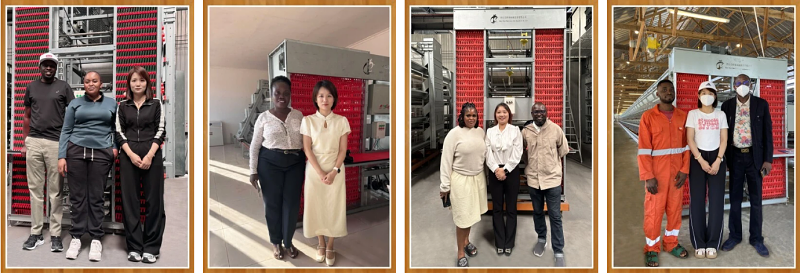

Vanke's chick battery cage is using in customer 's poultry farm.

Chick battery cage we introduced here is mainly rearing baby egg laying chicken, chick battery cage also is named to pullet cage or brooder cage. if you want to learn baby broiler cage, please check broiler cage.

VANKE chick cage rears baby egg laying chicken from one day old chicks, after 12 weeks or 16 weeks it grows up and near egg laying time, farmers will transport them to egg laying chicken battery cage also named layer battery cage, finish the whole rearing processing.

1. Easy to give food and water for one day old chicken

(1) In every cell of VANKE chick cage there are 1KG feeders and 1L drinkers, so you do not need to worry about chick’s feeding and drinking, after baby chick growing up to 1 week or 2 weeks, chicks could eat by feeding trough on cage, these small drinkers and feeders will move from cage.

(2) As chicks growing up and higher, the drinking pipes and nipple drinkers will rise, it adjust only two times in the whole rearing processing.

2. Cage structure easily adjust for different age chicks

Between one day old chicks and 2 weeks, chicks request comfortable standing place, VANKE put plastic mesh on bottom cage mesh, it is softer and more flexible, greatly improve rate of survival, plastic mesh will be moved after 2 weeks to make sure bottom cage is better service for growing egg laying chicken.

Accessories Of Chick Battery Cage

1. Cage mesh and frame

2. Automatic drinking system

3. Manual feeding system

4. Automatic manure cleaning system

5. Environmental control and auxiliary accessories (selective assembly)

6. Poultry house management (selective assembly)

Components And Working Principle Of Chick Battery Cage

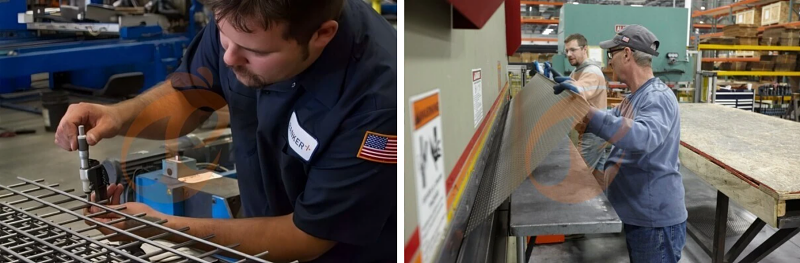

1. Cage mesh and frame

Stronger galvanized material

- Components: Bottom mesh Φ2.0–2.3mm, side/partition mesh Φ1.8–2.0mm, main frame Φ3.5–4.0mm, galvanized channel steel/angle steel columns, reinforcing rods, plastic floor mesh for chick foot protection, installation connectors (bolts, clips, hooks, brackets).

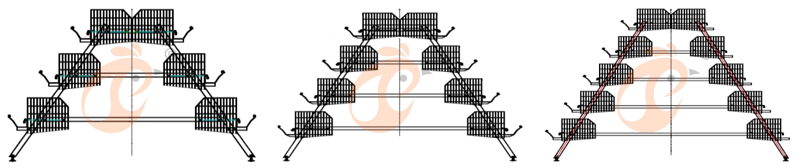

- Working principle: A-type cage structure with 3–4 tiers, stable frame design, and plastic mesh protects chicks’ feet.

2. Automatic drinking system

Water line and drinker

- Components: PVC water pipe, chick-type low-pressure nipple drinkers, water regulator, water tank, doser, installation connectors.

- Working principle: The system provides stable water supply, chicks drink by pecking nipples, the drinking line height can be adjusted as chicks grow, and the doser allows automatic delivery of medicines or nutrients.

3. Manual feeding system

Small feeder for young chick eating

Wroker adds food

- Components: Feed troughs, anti-waste baffles (optional), installation connectors.

- Working principle: Feed is manually distributed into the troughs, simple and reliable, with lower investment costs.

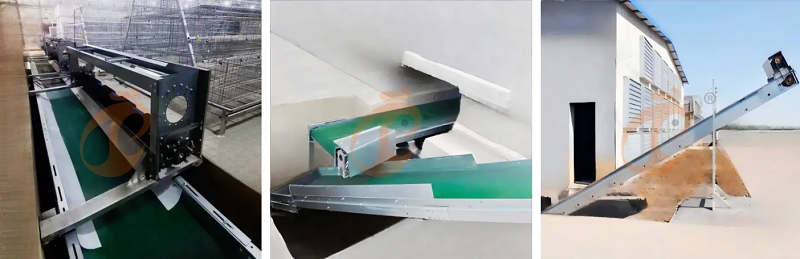

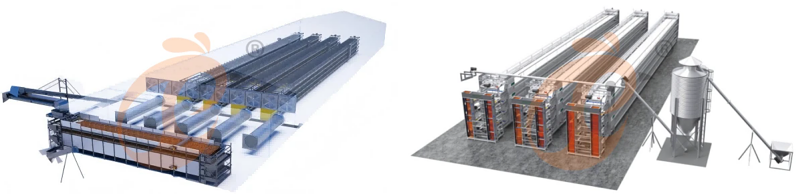

4. Automatic manure cleaning system

- Components: Longitudinal manure belt, cross transmission system, motor with chain drive, manure cart, scraper board, installation connectors.

- Working principle:

Type 1 belt cleaning to outside

(1) Belt type: Manure falls onto the manure belt, which is driven by motor to carry it outside at set intervals.

Type 2 scraper cleaning to outside

(2) Scraper type: Manure drops into the gutter, where a scraper chain moves back and forth to collect and remove it.

Customers can choose either method according to their farm size and budget.

5. Environmental control and auxiliary accessories (optional)

Pads, fans and fresh windows

Warm pipe and warm machine

- Components: Fans, cooling pads, LED lights, simple curtains, warmer, temperature and humidity sensors, anti-escape bars, anti-rat nets, installation connectors.

- Working principle: Provides basic ventilation, lighting, and temperature adjustment, ensuring a suitable growth environment for pullets.

6. Poultry house management (selective assembly)

Farm management APP

Control device and sensors

- Components: Farm CCTV, AI data analysis report, control device, NH3 sensor, other sensors and so on.

- Working principle: One-stop management and control, from CCTV to giving order to every house, from date collection to AI data analysis report of feed, growing and so on, abnormal condition detection and alarm system.

Specific configurations are subject to customer requirements or final quotation.

If you are interested in other equipment of AI smart management, layers, broilers, pullets, feed, eggs, manure and so on, please directly click PRODUCTS

Specification of A type semi-automatic chick battery cage

Cage cell

3 Tiers, 4 Tiers, 5 Tiers

| Tier/Set | Size(L x W x H)/Unit(Mm) | Cell Size(L x W x H) | Cells/Unit Per Set | Birds/Cells | Birds/Set | Space/Bird(m2) |

| 3 | 2 x 2.05 x 1.45 | 65 x 50 x 34 | 18 | 6 - 7 | 80 | 0.054 |

| 4 | 2 x 2.05 x 1.9 | 65 x 50 x 34 | 24 | 6 - 7 | 107 | 0.054 |

| 5 | 2 x 2.05 x 2.35 | 65 x 50 x 34 | 30 | 6 - 7 | 133 | 0.054 |

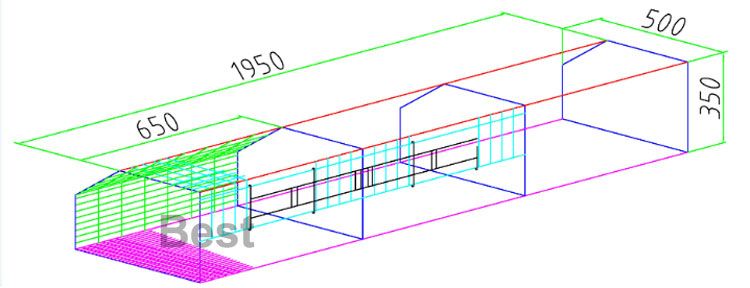

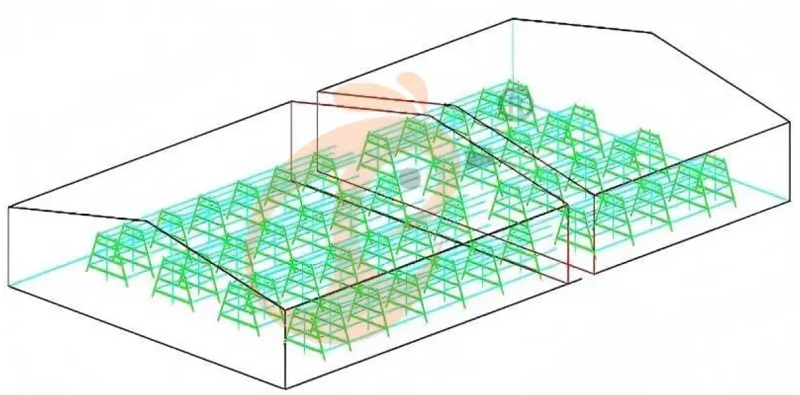

Capacity of different house size

Layout of battery cage system in poultry house

| Component | Regular Data | ||

| Cage Model | 3tiers | 4 tiers | 5 tiers |

| House Size:50 x 8 x 6.1-12.6 (L x W x H) | 5,520 birds | 7,383 birds | 9,177 birds |

| House Size: 100 x8 x 6.1-12.6 (L x W x H) | 11,520 birds | 15,408 birds | 19,152 birds |

| Standard Cage Dimension (L x W x H) | 2 x 2.05 x 1.45m | 2 x 2.05 x 1.9m | 2 x 2.05 x 2.35m |

| Birds Per Set | 80 birds | 107 birds | 133 |

Place the day old chicken cages on the first and second layers, and leave the third layer empty. When the chicks grow to a certain age, place them evenly on each layer.

For reference only, the exact size is based on the actual needs of the poultry farm and customer requirements, or our exact quotation.

1. Since its establishment in 2011, we have rich experience in localization services.

Nigerian local team

2. Constant communication with the United States and Europe, make high-quality battery cage and equipment.

Engineer inspection

3. Lagos local production, save customers 10% to 30% of costs.

Nigerian Factory, workshop and materials

4. Constantly innovate technologies, tailor intelligent project solutions for you.

Intelligent solution

5. Constantly expanding the team, the headquarters in Hong Kong and branches in Nigeria, Tanzania and Ethiopia are joint management.

Branches of China, Nigeria, Tanzania and Ethiopia

Vanke Machinery & Equipment Nig Ltd have serviced farmers and distributors since 2010.

Gain the high trust and recognition from customers to now.

Following farmers are some of our clients, welcome you!

Contact: Whatsapp 24 hours online +234 8111199996.

ADD: after Sinoma Office, 200 meters near Danco Filling Station, Lagos/Ibadan Expressway, Lagos State, Nigeria.

1. All fittings are packed by wooden pallets and boxes, plastic wraps and boxes, nude packing, it depends.

2. Local factory and warehouse from branches of Ethiopia, Tanzania and Nigeria, depends on your order.

3. Full or less container from China branch by sea, depends on your order.

Nigerian factory, warehouse and delivery

Container shipping from China to Nigeria

Engineer installation

4. Replace the nipple drinkers if they link water to protect brid feather, medicinal water will make feather fall off.

...

Contact us now to get full helpful information.

SEND YOUR MESSAGE TO US

(* We will reply your inquiry to this Email as soon as we see it.)RECENT BOLGS

Comments

CONTACT US